Polyethylene is one kind of polymer that very popular plastic in the world, this kind of polymer usually makes shampoo bottles, soap bottles, tail lamps, inner panels, electrical and mechanical gear, children toys, grocery bags and little electrical parts components like in printer, vacuum cleaner and others , poly mean “ many” and mer is part, so we can easy define polymer as many parts and the molecule of polymer has usually repeatedly in a chain-like manner. Those parts is called monomers, same structural monomer connected by covalent chemical bound.

Furthermore, Polyethylene is many ethylene that bound by covalent chemical bond, The International Union of Pure and Applied Chemistry (IUPAC) have recommended scientific name 'polyethene' , because IUPAC give name ethylene as ethene.

In industrial name line mold engineer of plastic engineer polyethylene is common called by PE. Is same with PS for polystyrene.

Ethene or Ethylene Molecule

as we know ethene (IUPAC) or ethylene consist of C molecule and H molecule with CH2=CH2 or C2H4, ethene as very simple structure. picture at left side shown the monomer of ethylene.

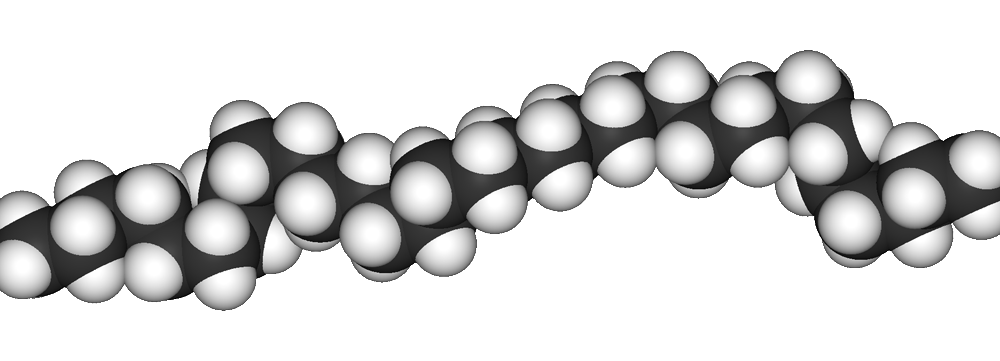

the illustration of polyethylene you can see at picture below, one monomer of ethylene connected with other with a hundred monomer and become polyethylene

polyethylene chain picture

Polyethylene Industrially Practice

The first time polyethylene synthetical industrially practices was discovered by Eric Fawcett and Reginald Gibson at ICI Chemicals in 1933.

in 1935, another ICI chemist, Michael Perrin, start to develop a reproducible industrial synthesis for low density polyethylene (LDPE)

Using Catalyst

in 1951 by Robert Banks and John Hogan at Phillips Petroleum discover chromium trioxide based catalyst

In 1953, the German chemist Karl Ziegler developed a catalytic system based on titanium halides and organoaluminium compounds that worked at even milder conditions than the Phillips catalyst(http://www.otm-it.com/)

Producing polyethylene

how to produce polyethylene polymer ? Polyethylene both in industrially and laboratory produce by polymerization process, this process connected monomer or a mixture monomer become together by reaction that results a chain like form called polymer.

They are three methods that commonly to produce polyethylene in polymerization process

1. Radical polymerization

2. Anionic addition polymerization

3. Ion coordination polymerization (cationic addition polymerization )

Classification

The system of classification of polyethylene based on weight and density are

1. Ultra high molecular weight polyethylene (UHMWPE)

2. High molecular weight polyethylene (HMWPE)

3. High density polyethylene (HDPE)

4. High density cross-linked polyethylene (HDXLPE)

5. Medium density polyethylene (MDPE)

6. Low density polyethylene (LDPE)

7. Linear low density polyethylene (LLDPE)

8. Very low density polyethylene (VLDPE)

9. Ultra low molecular weight polyethylene (ULMWPE – PE-WAX)

10.Cross-linked polyethylene (PEX)

Polyethylene Characteristics

This material is known for its purity, elevated hardness, surface shine, resistance to abrasion, good rigidness and, in general, its excellent resistance to chemical agents. Its temperature of use can reach up to 110°C.

JIS testing Method

using standard test K6911 and K7112, this test equivalent with ASTM testing method D792, the results is :

Molding Shrinkage Rate (%)

LDPE shrinkage rate = 1.5 – 5.0

MDPE shrinkage rate = 1.5 – 5.0

HDPE shrinkage rate = 2.0 – 6.0

Compression Molding Pressure (kgf/cm2)

LDPE = 7.03 – 56.2

MDPE = 7.03 – 56.2

HDPE = 0.35 – 0.56

Injection Molding pressure (kgf/cm2)

LDPE = 562 – 2110

MDPE = 562 – 2110

HDPE = 703 – 1410

learn the new technology and tutorial in plastic engineering, polymer material technology